HLZ® DD

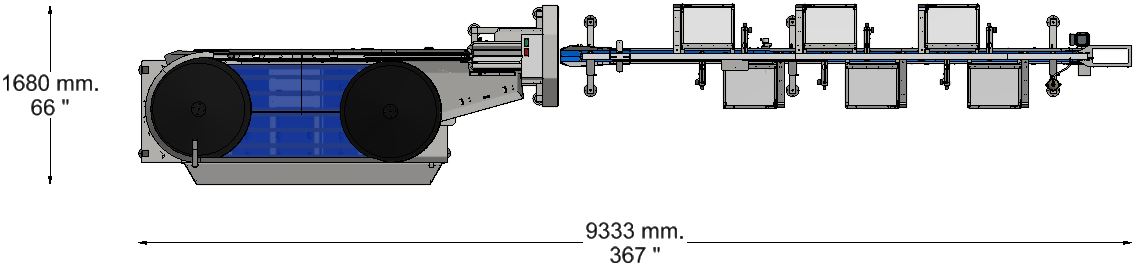

The Duo Disc HLZ® DD is an industrial high-speed counting and sorting machine designed for processing both refillable and non-refillable used beverage containers.

This system features a Duo Disc module with a double conveyor lane to spread containers equally and process each container at very high speed through the inliner.

Utilizing our patented inliner technology and our ring scanner technology with 360˚ detection of barcodes the machine is capable of handling any mix of PET bottles, aluminum cans and glass bottles (Tetra Paks and gable tops are optional).

The machine is constructed from stainless steel (AISI314) and is designed for high durability.

- Barcode reading system designed to count and sort containers based on materials or brands

- PET bottles, aluminum cans, glass bottles

- 100-300 containers/minute

- Registration accuracy: ≥99.5%

- Up to 32 sorting stations

Technical specifications

| Dimensions | Customizable |

| Stations | Customizable |

| Power supply | 3 phase + N + PE |

| Power cons. (kW) | 3.25 |

| Detection | 360˚ detection of barcodes |

| Inliner | Duo Disc (DD) |

| Infeed | Integrated feeding conveyor |

| Network 1 | LAN HLZ® Easy/VPN for remote support |

| Network 2 | LAN for counting data transmission |

| Construction | Stainless steel AISI304 |

| Capacity | 100-300 containers/min. |

| Registration accuracy | ≥99.5% |

| Container types | PET, aluminum cans, glass |

| Container shape | Cylindrical Ø50-130 mm |

| Min. ratio cylindrical | Length/diameter(Ø) 1.4 |

| Container length | Up to 400 mm/16’’ |

| Ambient temp. | Min. 7˚C/44˚F max.+40˚C/104˚F |

| Certification | CE, UL, CSA, SAA |