Products

Counting and sorting – material

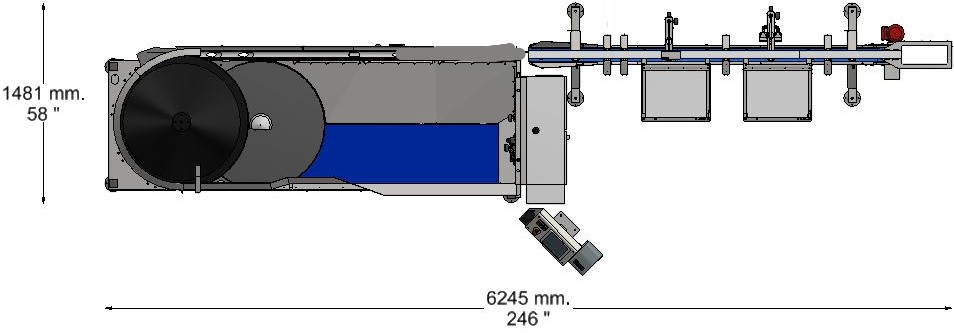

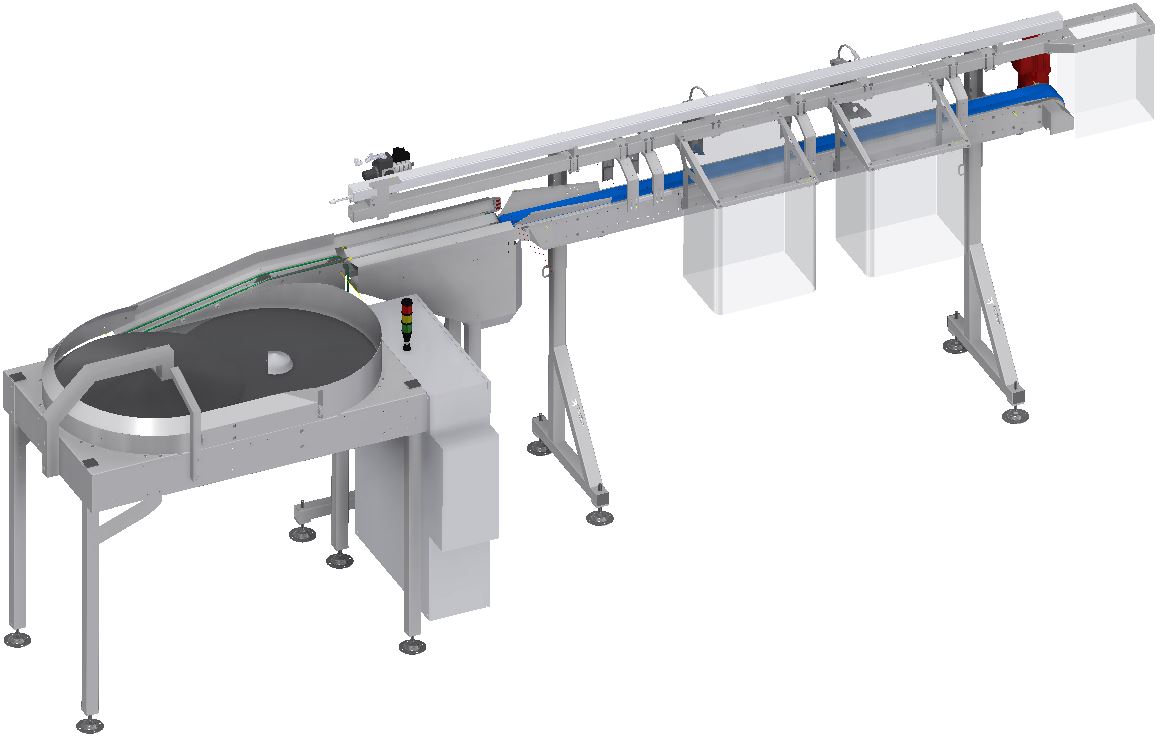

HLZ® MDU C MS

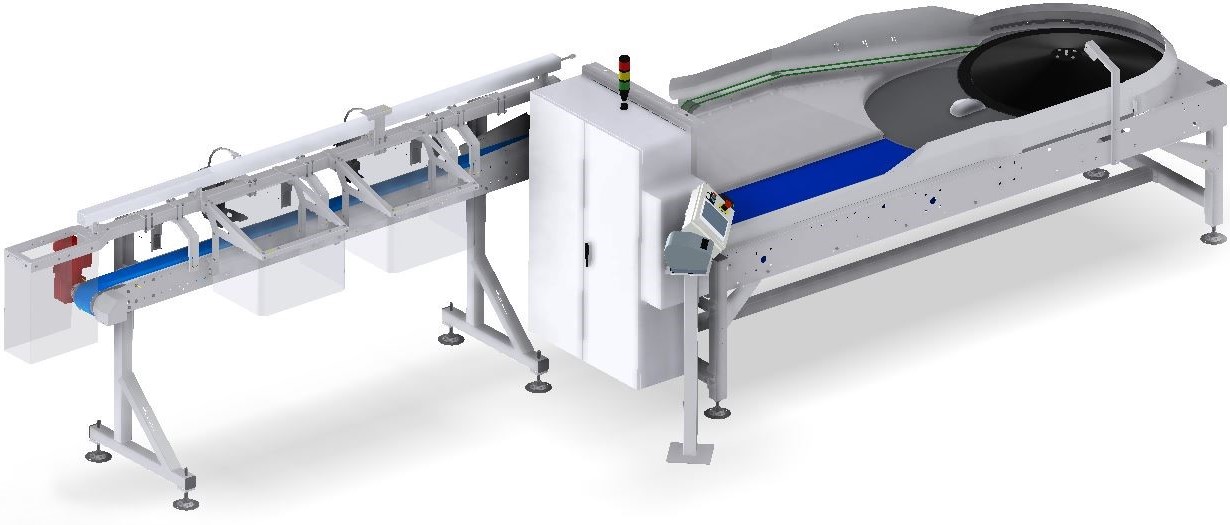

The HLZ® MD Ultra C MS is an industrial high-speed counting and sorting machine designed for processing refillable and non-refillable used beverage containers.

This machine features a metal detector and soft blow technology to sort any mix of PET bottles, aluminum cans and glass bottles.

The HLZ® MD Ultra C MS has an integrated feeding conveyor to process large quantities of used beverage containers at high speed.

- Counting and sorting systems designed to count and sort materials

- 100-300 containers/minute

- Registration accuracy: ≥99.5%

- Stainless steel construction (AISI304)

- Batch scanner for pre-tagged bags

- Batch printer

Technical specifications

| Dimensions | Customizable |

| Stations | Customizable |

| Power supply | 3 phase + N + PE |

| Power consumption (kW) | 1.75 |

| Detection | Metal detection and soft blow |

| Inliner | Mono Disc Ultra (MDU) |

| Infeed | Integrated feeding conveyor |

| Network 1 | LAN HLZ® Easy/VPN for remote support |

| Network 2 | LAN for counting data transmission |

| Construction | Stainless steel AISI 304 |

| Capacity | 100-300 containers/min. |

| Registration accuracy | ≥99.5% |

| Container types | PET, aluminum cans, glass |

| Container shape | Cylindrical Ø50-130 mm |

| Min. ratio cylindrical | Length/diameter(Ø) 1.4 |

| Container length | Up to 400 mm/16’’ |

| Ambient temp. | Min. 7˚C/44˚F max.+40˚C/104˚F |

| Certification | CE, UL, CSA, SAA |

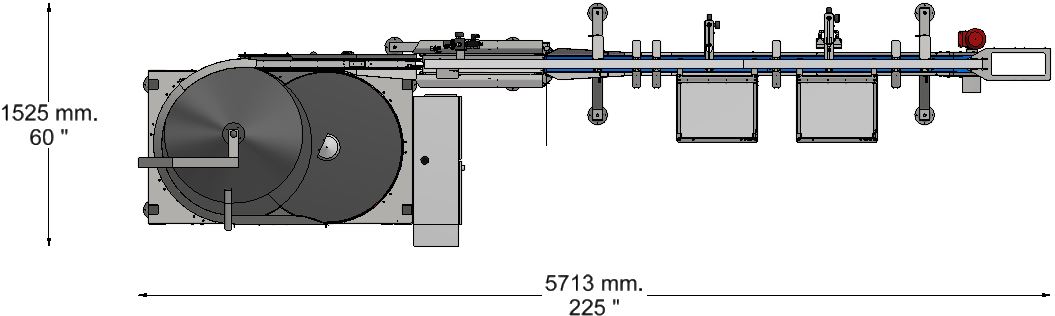

HLZ® MD C MS

The HLZ® MD C MS is an industrial high-speed counting and sorting machine designed for processing refillable and non-refillable used beverage containers.

This machine features a metal detector and soft blow technology to sort any mix of PET bottles, aluminum cans and glass bottles.

The HLZ® MD C MS has an integrated feeding conveyor to process large quantities of used beverage containers at high speed.

- Counting and sorting system designed to count and sort materials

- Any mix of beverage containers

- 50-150 containers minute

- Registration accuracy: ≥99.5%

- Stainless steel construction (AISI304)

Technical specifications

| Dimensions | Customizable |

| Stations | Customizable |

| Power supply | 3 phase + N + PE |

| Power consumption (kW) | 1.37 |

| Detection | Metal detection and soft blow |

| Inliner | Mono Disc |

| Infeed | By optional external feeder |

| Network 1 | LAN HLZ® Easy/VPN for remote support |

| Network 2 | LAN for counting data transmission |

| Construction | Stainless steel AISI 304 |

| Capacity | 50-150 containers/min. |

| Registration accuracy | ≥99.5% |

| Container types | PET, aluminum cans, glass |

| Container shape | Cylindrical Ø50-130 mm |

| Min. ratio cylindrical | Length/diameter(Ø) 1.4 |

| Container length | Up to 400 mm/16’’ |

| Ambient temp. | Min.7˚C/44˚F max.+40˚C/104˚F |

| Certification | CE, UL, CSA, SAA |

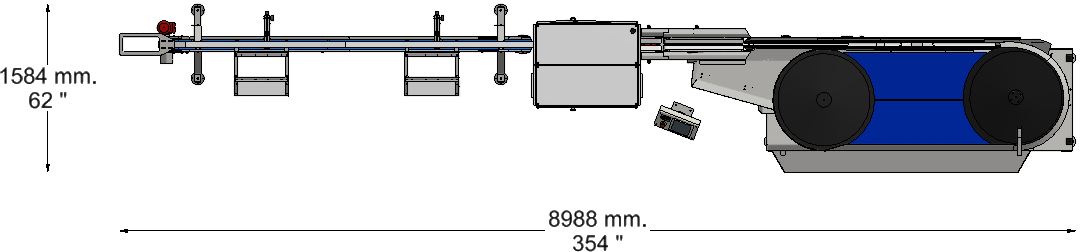

HLZ® DD C MS

The HLZ® DD C MS is an industrial high-speed counting and sorting machine designed for processing refillable and non-refillable used beverage containers.

This machine features a metal detector and soft blow technology to sort any mix of PET bottles, aluminum cans and glass bottles.

- Counting and sorting system designed to count and sort materials

- 100-300 containers/minute

- Registration accuracy: ≥99.5%

- Batch scanner for pre-tagged bags

- Batch printer

Technical specifications

| Dimensions | Customizable |

| Stations | Customizable |

| Power supply | 3 phase + N + PE |

| Power consumption (kW) | 2.75 |

| Detection | Metal detection and soft blow |

| Inliner | Duo Disc |

| Infeed | Bulk feeder of 1 m3, 2 1/2 m3 or 4 m3 |

| Network 1 | LAN HLZ® Easy/VPN for remote support |

| Network 2 | LAN for counting data transmission |

| Construction | Stainless steel AISI304 |

| Capacity | 100-300 containers/min. |

| Registration accuracy | ≥99.5% |

| Container types | PET, aluminum cans, glass |

| Container shape | Cylindrical Ø50-130 mm |

| Min. ratio cylindrical | Length/diameter(Ø) 1.4 |

| Container length | Up to 400 mm/16’’ |

| Ambient temp. | Min.7˚C/44˚F max.+40˚C/104˚F |

| Certification | CE, UL, CSA, SAA |

Contact

If you want to learn more about our HLZ® systems and how we work, please contact us.