-

Ring

Tlf: +45 7033 2233 -

E-mail

info@anker-andersen.com

Produkter

Bottle Depots and Redemption Centers

Bottle Depots and Redemption Centers

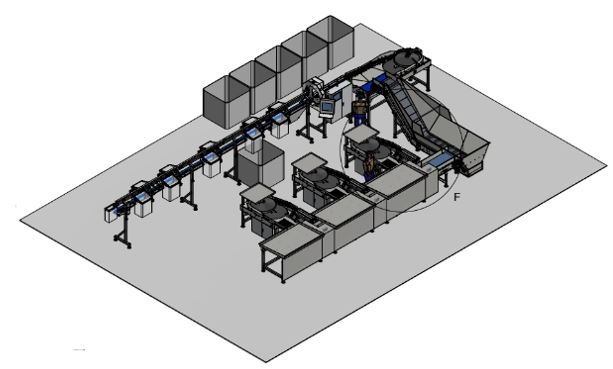

The HLZ® MD Ultra (MDU) systems integrate industrial high-speed front-end counting machines with back-end sorting machines designed to process a diverse range of used beverage containers.

The systems stand out as the ideal solution for US Redemption Centers seeking counting and sorting of containers by brand at high speed and with great accuracy. Canadian Bottle Depots will benefit from flexible solutions tailored to accommodate both capacity and space requirements.

The HLZ® systems handle with great efficiency any mix of PET bottles, aluminum cans, glass bottles and Tetra Paks, and constructed from stainless steel (AISI304) they are designed for high durability.

- Barcode reading systems designed to count and sort containers based on materials or brands

- Customized solutions to meet customers' volumes and space limitations

- Up to 300 containers/minute

- User-friendly sorting tables at the front-end

- Connection conveyors between front-end and back-end

- Optional light curtains for odd shape containers

- Up to 32 sorting stations depending on sorting schemes

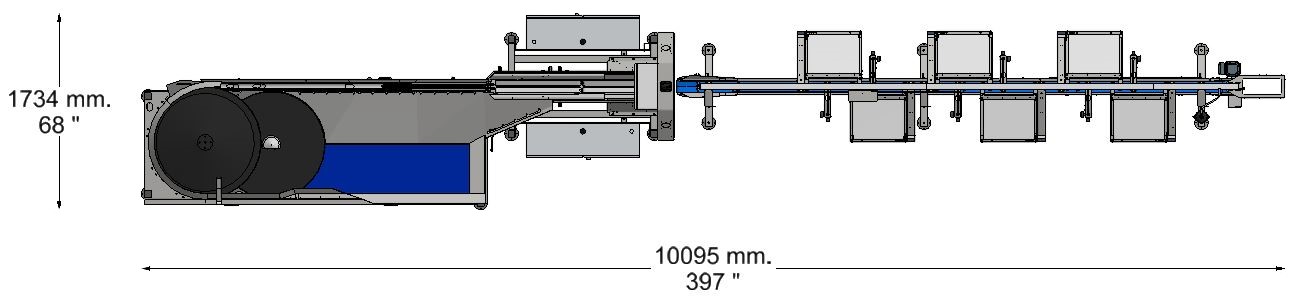

Technical specification of HLZ® MD Ultra

| Dimensions | Customizable |

| Stations | Customizable |

| Power supply | 3 phase + N + PE |

| Power consumption (kW) | 3.0 |

| Detection | 360˚ detection of barcodes |

| Inliner | Mono Disc Ultra (MDU) |

| Infeed | Integrated feeding conveyor |

| Network 1 | LAN HLZ® Easy/VPN for remote support |

| Network 2 | LAN for counting data transmission |

| Construction | Stainless steel AISI304 |

| Capacity | 100-300 containers/min. |

| Registration accuracy | ≥99.5% |

| Container types | PET, aluminum cans, glass |

| Container shape | Cylindrical Ø50-130 mm |

| Min. ratio cylindrical | Length/diameter(Ø) 1.4 |

| Container length | Up to 400 mm/16’’ |

| Ambient temp. | Min.7˚C/44˚F max.+40˚C/104˚F |

| Certification | CE, UL, CSA, SAA |

Contact

If you want to learn more about our HLZ® systems and how we work, please contact us.